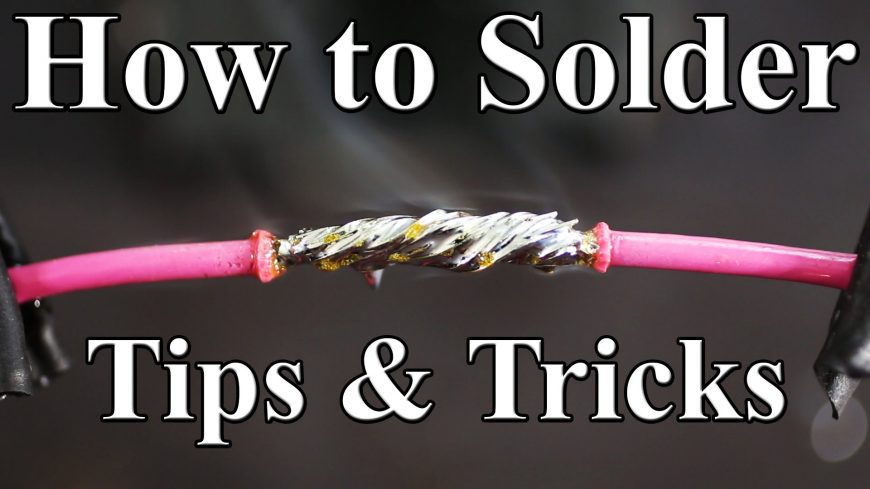

How to Solder Wires Together… Best Tips and Tricks!

Chris Fix has one of our favorite YouTube channels due to his wide-ranging knowledge of all-things automotive and easy-to-understand way of delivering his expertise, making even the biggest jobs seem possible for all of us out here with the want-to and not the know-how.

While most of his videos show how to carry out an actual install or project, sometimes he takes the time to teach his viewers skills that they can use across a host of projects for years to come. One such skill that I can certainly use a little education on is soldering, so when I saw this video on Chris’ channel, I knew I had to check it out, and as usual, he does and excellent job of teaching the technique as an easy-to-follow process that will help anybody out there who is going to be doing any wiring projects.

To put it in terms a lot of us should be able to understand, soldering is basically welding wires together. Applying heat to the wires and the solder, which is a fairly soft metal that melts easily and cools quickly to fuse the individual strands together, building a strong, conductive connection. There’s also a sponge involved, which is used to wipe old solder and oxidation off the soldering tip to make sure the tip is clean and ready to use. Using a wax-like substance called flux will help the solder flow into the strands of the wires and protect them from oxidation or corrosion, so be sure to coat both wires in flux before you start to solder them.

To cover the connection, use a short length of heat-shrink tubing to protect the wire and keep it from shorting out and causing all kinds of headaches.

Thanks as always to Chris Fix for his awesome information and great delivery. We can’t wait to find something around the shop that needs some wiring done now, so we can try out these tips and tricks!