The Life of a Gear

Gears easily qualify as one of the most useful inventions of all time. They are absolutely essential to the automotive industry, and have countless other uses throughout the world. If you’ve ever wondered just how gears come to exist, the video below takes an in-depth look at one gear-making process, all the way from design to its use in the wheel of a student-built race car.

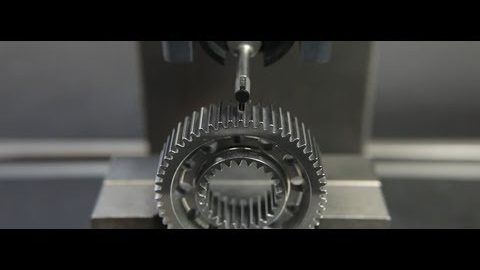

The video opens in a design lab, where a CAD designer is creating a virtual model of the gear on his computer. From there, the design is sent to the machine shop, where a metal disk is chosen, machined down to the proper thickness, then sent to a laser cutter, which cuts out the exact shape from the emailed design. A series of measurements are taken to ensure everything is exactly as needed for the end product. The gear is then shipped to a polishing facility, where it undergoes a multi-step polishing process that gives it a nice shine. Finally, another series of measurements are taken to reveal the quality of the finish, then it’s shipped to the race facility for assembly.

The gear is placed inside the hub assembly of a Formula Student Racecar, where you can see from the outside perspective just how small it is in relation to the car itself. However, if even one tiny gear fails to perform as expected, it could mean disaster for the race team, which is why even such a small part has to undergo such rigorous and careful processes while it’s being made. The Formula Student Racecars are really cool electric racecars that are built and raced by teams of students from various universities. These teams research and design as much of the car as possible on their own to help further their education and give them real world experience they can use later down the road.