Using Friction to Melt Holes in Steel… AKA Flow Drill

Not long ago, we shared a video featuring a look at friction welding, which – dumbing it down to the sake of space – is when two pieces of metal are pressed together and one of them spun to high RPM’s, the friction causing both metals to heat and liquify. The rotation is stopped while the pressure is maintained, and the metals fuse as they cool.

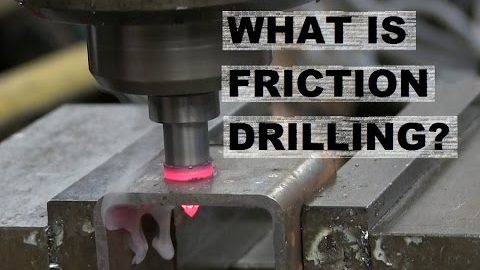

Flow drilling relies on some similar properties and behaviors to offer a new way to drill holes that will help increase the cross section of thin walled tubing, making it easier to tap and add threads to. The principle is pretty basic: use an incredibly hard metal and friction to heat the metal to it’s melting point and force the hardened “bit” through using pressure from the milling machine.

YouTuber AvE walks us through several test drills while giving a thorough explanation of the metals involved and the process itself. We get to see a few successful test drills before he finally gets too aggressive and breaks one of the bits at the end. Go ahead and check out this clip and educate yourself, you never know when you may need to use this process yourself!