Up Close Footage of Linear Friction Welding… Amazing

We’ve shared videos of friction welding before, but the process is just so fascinating and satisfying to watch that we decided to share some more footage with you today. This video, from TWI Ltd’s YouTube channel, gives us a nice close-up look at the process while sharing a little bit about the how’s and the why’s linear friction, or Linfric welding is used.

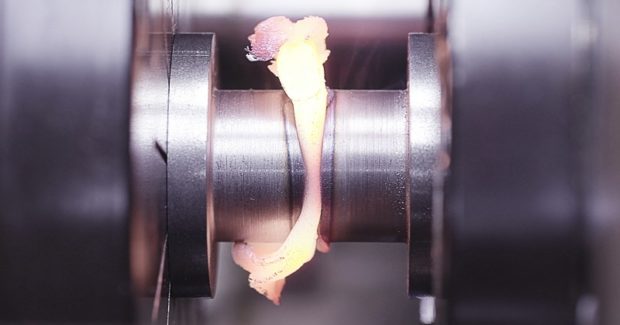

The process is used to join metals just like traditional welding, except linfric creates a solid joint that melds the whole surfaces of both pieces being welded, resulting in a more uniform joint that provides excellent strength. The process also results in a more controlled and even heating of the metals, which helps reduce fatigue caused by uneven or extreme heat used in traditional welding methods. Plus, to channel our inner child, the process is just plain cool to watch. One piece is held stationary while the other is vibrated rapidly against it. As the friction grows, so does the heat, which eventually reached the melting point of the material, at which point pressure is applied, forcing the two pieces together.

Once the proper force has been applied, the vibration stops and the cooling process actually fuses both pieces together into a solid rod. The molten metal that’s been forced out of the joint will be cleaned away and the process results in a clean, durable joint that has a nice, uniform appearance. The video discusses some of the uses for the process, as well as a couple of the advantages. I have a friend here in Huntsville, Alabama who is very familiar with this process due to his work with NASA on various projects on which linfric welding was used. I wish I had asked more about how the process works now, as I had no idea it was so cool to watch.