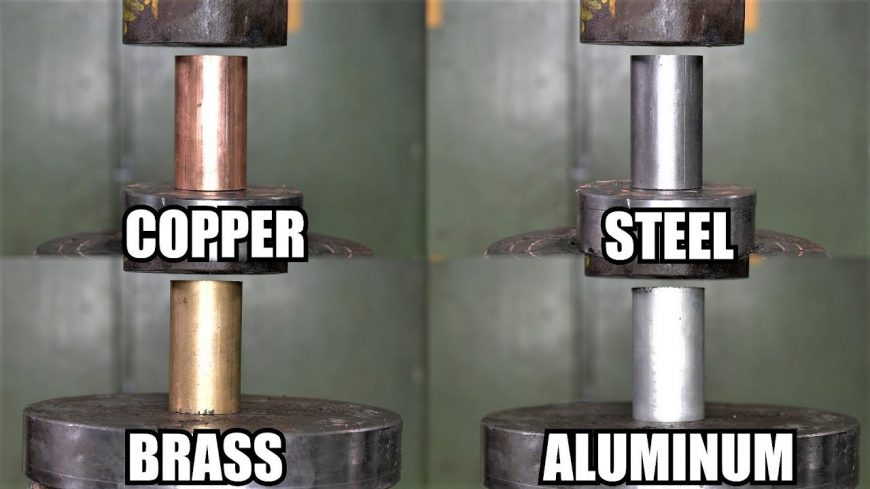

Brass, Copper, or Steel – Which Metal is Stronger? The Hydraulic Press Finds Out!

Those who have worked with metal in any capacity may have observed a couple of things. For example, different metals are better in different situations.

For somebody who is looking to build some sort of structural frame, they probably wouldn’t use something like copper. While copper is incredibly valuable, the price doesn’t mean that it’s going to be sturdy. In fact, it’s one of the more malleable metals. This means that it can be molded and bent rather easily. Its high conductivity makes it good for electric work. On the other hand, characteristics like their resistance to corrosion make it ideal for plumbing. It’s not hard to see how being an incredibly soft metal can be advantageous in some situations like pipe bending. However, it might not have much upside in something like building something like a roll cage in a racecar.

On the other hand, we have metal like steel. For somebody who is looking to build a frame for a building, perhaps, steel might be the right route to go. Not only does it have a good amount of structural integrity. The metal is also known to withstand the test of time, that is, if it isn’t exposed to the elements, at least. It also really helps out that it’s relatively cheap. When applying this to an entire building, the cost will definitely add up.

All of that aside, this time, we’re checking out a test that will show just how something like malleability acts in real life. In this test from the Hydraulic Press Channel, we get to see how much force a chunk of each metal can take before begins to bend. This is certainly a new take on seeing just how resistant certain metals are.

The crazy part about this one is that the demonstration manages to break a window in the process! Watch out for flying metal!