Micro-Welding Shrinks Down the Real Deal and it’s Amazing to See in Action

When it comes to welding properly, it’s both an art and a science as you need to have just the right hand motion along with the right tools and the right process in order to make it all come through smoothly. While it might seem like a fairly straightforward task, the job doesn’t always end up being that way as good welders usually have a lot of experience under their belts and practice along with it. Now, just imagine being good at welding and throwing everything that you know in the trash to start over again, doing welding and in all new fashion.

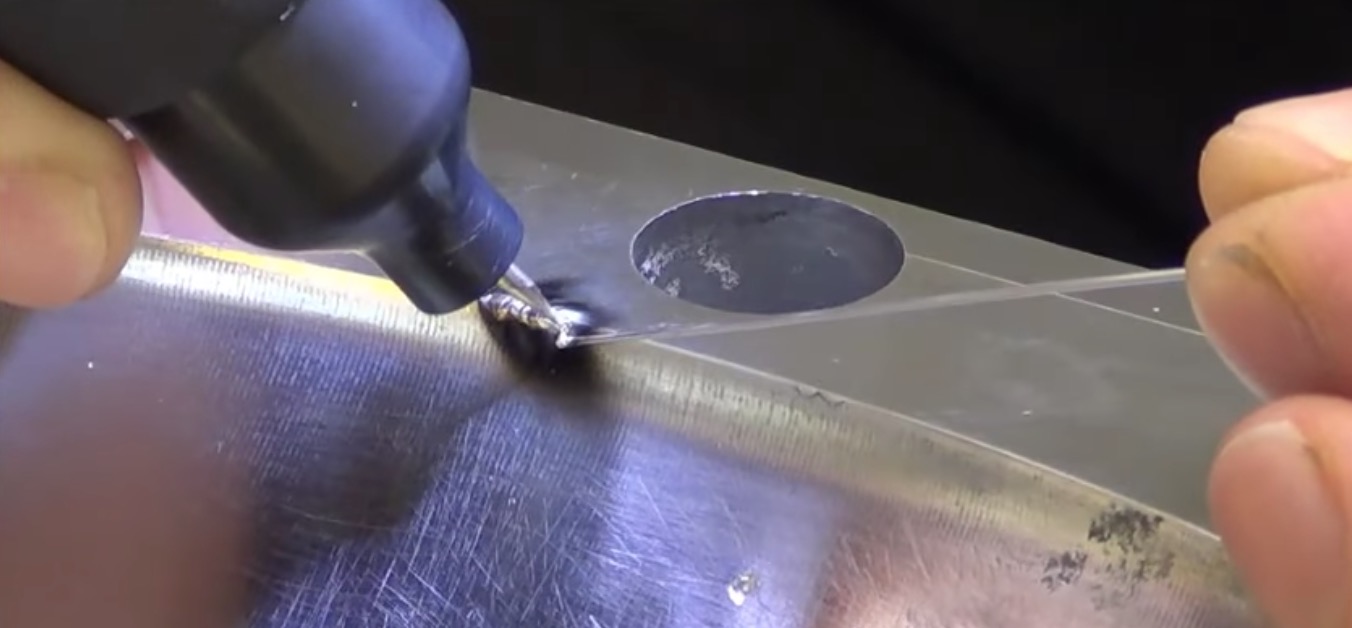

This time, we dig down deep into micro welding, basically a process that takes the real deal and shrinks it down to become tiny. I mean, when you think of it, this is definitely a process it seems like it’s obviously necessary and a part of products that we use every day, however, when you use things that have these tiny little welds on them, you really don’t think about how they come to be. In other words, this intermediate step in welding the other small little things isn’t something that anybody would really think about on a regular basis unless you’re familiar with the job.

Follow along down the video below as you’re able to get up close and personal with a couple of insanely shrunken down situations that really show you precision welding at its finest. Doing something like welding definitely takes a lot of ability and talent, but just imagine trying to be even more precise and hitting the perfect weld on something this tiny that is about the size of your fingernail if not smaller. After you see exactly what these guys get through to make sure that they’re tiny welds are perfect, tell us what you think of this physically small but big, in scope, job