Watching These Heads Being Resurfaced LS3 Extremely Satisfying

Over the years, we have brought you several videos from machine shops all across the country showing mills, lathes and CNC machines putting in work shape\ing and reshaping metal. Many of these videos are slow motion captured used to show us just how beautiful the process can be, while others are full-speed or even sped up to capture the whole process from beginning to end.

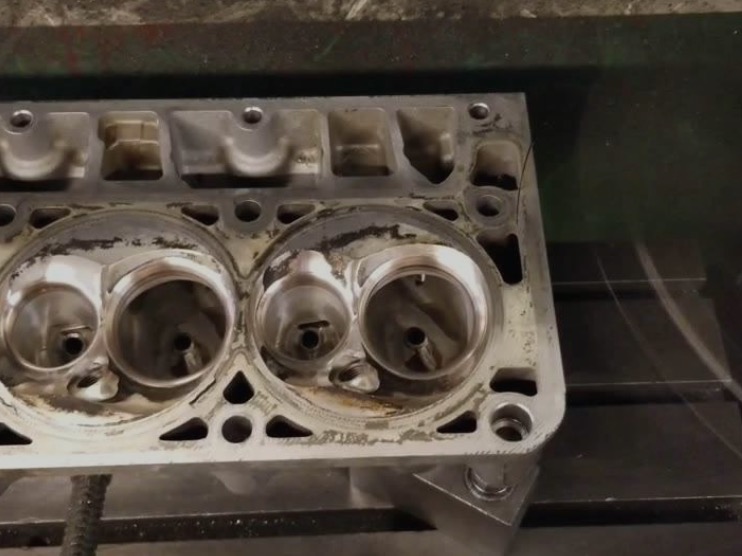

This video is regular speed and shows a mill cutting .015 of an inch off a set of LS3 cylinder heads. Cutting the heads like this can serve a couple of purposes that I know of, one being to repair a warped or damaged head and the other to increase performance. Unless we have specific details, there’s no way to say for sure which is the reason for this particular process, but we can discuss both.

If the heads have been warped or otherwise damaged, the surface of the heads that mates to the top of the block – with the head gasket in between, of course – may be compromised. That surface, known as the deck, has to be perfectly flat to ensure even clamping force between it and the block when the engine is being assembled because any imperfections could cause improper sealing and lead to premature gasket failure.

Of course, the heads could be fine, and their owner just wants a little more performance. How does shaving a little off the deck increase performance? Put simply: compression.

The combustion chamber itself is part of the head, and as the material is removed from the deck, it’s actually removing part of the area of the combustion chamber. So as the deck of the head gets shorter, the chamber gets smaller, which ups compression and increases performance. It’s a small difference, of course, and you’ll likely want to consider different pistons and a cam swap when you change compression, but in the pursuit of performance, every little bit helps!