Japan Tackles Traffic with New 310-Mile Long Underground Conveyor, Replacing Semi-Trucks

The Japanese Transport and Tourism Ministry has unveiled an audacious plan to tackle logistics efficiency, reduce road traffic, and address the severe labor shortage crisis Japan faces. They propose constructing a 310-mile fully automated underground transportation system to move packages between Tokyo and Osaka. While this idea may sound wild, it actually holds a lot of potential when you dig into the details and consider similar projects worldwide.

A Solution to Multiple Problems

This ambitious underground network promises several significant benefits. First, it aims to alleviate traffic congestion on some of Japan’s busiest highways. According to the Ministry, this new system could handle the cargo equivalent of 25,000 trucks per day. This shift would not only reduce traffic jams but also cut down on pollution. As Minister Tetsuo Siago stated, “[The project] will not only address the logistics crisis but also help reduce greenhouse gas emissions.”

However, the most critical issue this massive project addresses is the severe shortage of truck drivers. Japan’s population is shrinking at an alarming rate. The country lost 837,000 people in the year leading up to October 1, 2023, marking the largest annual decline since records began in 1950. This demographic shift equates to approximately 2,293 people per day, or 96 people per hour, not being replaced by new births. This decline has significantly impacted the workforce, with the working-age population dropping from a peak of 87 million in 1993 to 75.3 million in 2018. By 2030, the population is expected to decline further, exacerbating labor shortages in various sectors, including logistics.

The Logistics Challenge

The rise of online shopping has doubled the number of small parcel deliveries over the past 30 years. This surge has strained the current logistics infrastructure, and the situation is projected to worsen. The Ministry estimates that by 2030, 30% of packages will not be delivered due to labor shortages. This looming crisis has prompted Japanese authorities to act swiftly, aiming to complete the Tokyo-Osaka project by 2034. Minister Siago emphasized the urgency, stating, “We would like to speedily proceed with the discussions on the matter.”

The Plan in Detail

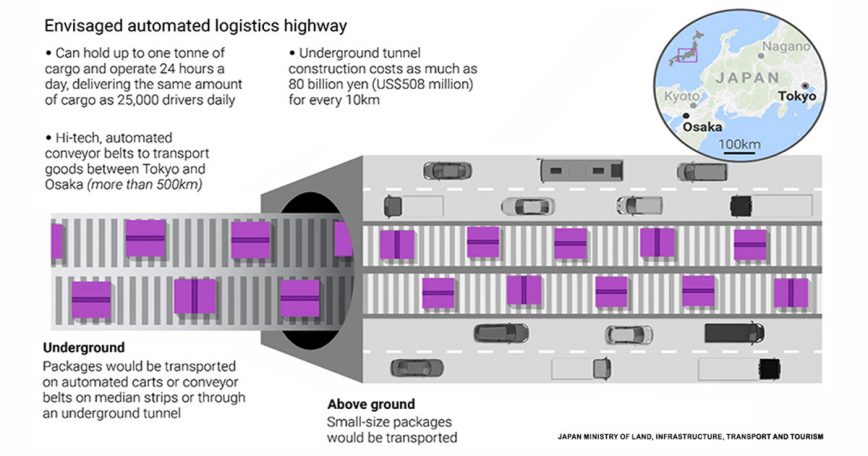

The proposed system will utilize fully automated, electric-powered pallets capable of carrying up to a ton of cargo each. Initially, these pallets were supposed to run on tracks in the median of existing highways. However, the government now leans toward tunnels beneath these routes. These smart pallets can transport various goods, from Amazon packages and agricultural products to fresh fish and daily necessities.

The route will stretch approximately 310 miles between Tokyo and Osaka, with construction costs estimated at up to $26 billion. Depending on the location, the construction costs will range from $48 million to $550 million for every six miles of tunnel. The Ministry acknowledges the challenges ahead, including structural and environmental hurdles typical of mega-infrastructure projects. To overcome these, they plan to involve the private sector in funding and create a dedicated organization to build and manage the new transportation system.

Global Trends in Underground Logistics

Japan isn’t alone in exploring high-tech solutions to logistics problems. However, its project stands out for its ambition and complexity due to the high population density in Japanese cities. Countries like Switzerland, China, and the Netherlands are also working on similar systems.

Switzerland’s Cargo Sous Terrain (CST) project, for example, aims to create a 310-mile network of underground tunnels for cargo transport, connecting major Swiss cities like Zurich, Basel, and Geneva by 2045. This system will use automated, driverless electric vehicles traveling at a constant speed of 19 mph. The estimated cost for the first section from Härkingen-Niederbipp to Zurich is around $3.6 billion, while the entire network is projected to cost $33 to $38 billion. Unlike Japan, Switzerland’s goal isn’t to address a workforce issue but to reduce CO2 emissions and ease urban traffic congestion.

China is developing the Urban Underground Logistics Systems (ULS) in cities like Beijing and Shanghai. These systems use automated guided vehicles (AGVs) and conveyor belts to transport goods through extensive underground tunnels. Conceptualized in the mid-2010s, the initial operational stages are expected by 2025, with progressive network extensions by 2035. These projects typically cost between $3 and $4.5 billion and aim to improve logistics efficiency and reduce surface traffic congestion.

The Netherlands is also exploring underground freight transport systems, focusing on large-diameter tunnels connecting urban distribution centers with key transport hubs like airports and seaports. These projects involve automated systems similar to conveyor belts and AGVs. With costs ranging from $11 to $16 billion, initial pilot projects are expected to be operational by 2030, with full-scale implementation targeted for 2040.

The Future of Logistics

Japan’s project stands out because it focuses on a single critical corridor, one of the busiest in the country. This ambitious plan could revolutionize logistics, making it more automated, efficient, and less dependent on human labor. The concept of using conveyor belts for cargo isn’t new; it has evolved from rudimentary hand-cranked versions in the late 1700s to modern heavy-duty belts used in mining. Today, conveyor belts transport sushi, take us to airport gates, and keep us running on treadmills. Tomorrow, they might just transport our packages hundreds of miles underground.

The commercial truck driver shortage isn’t just a Japanese problem; it’s a global issue. In the U.S., for example, the DRIVE SAFE Act suggests opening the profession to 18-year-olds, while some states have increased load limits. Japan’s proposed solution—a 310-mile-long conveyor belt—might seem unconventional, but it could be the answer to the logistics challenges posed by a declining and aging population.

Conclusion

Japan’s plan for an underground logistics network between Tokyo and Osaka is bold and innovative. By addressing multiple issues simultaneously—traffic congestion, pollution, and labor shortages—this project has the potential to transform the logistics industry. While there are significant challenges to overcome, the benefits could be enormous, setting a precedent for other countries facing similar issues. As technology and infrastructure evolve, the future of logistics might just lie beneath our feet.